KRIAUTE LLC was founded in 1987, in Lithuania. We have 10000m2 of manufacturing space, where we produce timber frame house panels, wooden windows and doors, structural and planed wood, different kinds of joinery products, garden houses and outdoor furniture.

TIMBER FRAME HOUSES

Timber-frame element houses production plant was launched in 2007. It is one of the most modern plants of this kind in the Baltic States. Modern production line equipment obtained from Sweden. The estimated production yield is 1000 sq. m. of living area per month.

QUALITY CONTROL

KRIAUTE LLC implemented ISO 9001:2008, ISO 14001:2004, OHSAS 18001:2007 management system standards.

The main quality control principles are:

• the house elements are made indoors

• pre-fabricated elements are made by using computerized equipment, therefore the human impact on precision and quality of the final product is reduced

• every house element passes quality control in the production-shop

• only specially-trained highly-skilled employees work in the production area

• in the course of production process we focus our attention on technical solutions ensuring high quality of products

• only highest-quality, certified wood with 15 % moisture content is used for production of elements.

BUILT PROJECTS

SHOW HOUSE. Houses built in Norway, Lithuania, Ireland, France, Sweden, Denmark, Belgium

Quality control system, highly-qualified personnel and the use of certified building materials guarantee rapid production process and high quality of the products. Our company cherishes its reputation. We carefully meet our commitments and seek to remain a reliable partner. We offer warm, economical and safe houses to private clients and companies

KRIAUTE, LLC was founded in 1987, in Lithuania. In 2007, the company finished the implementation of the project Manufacture of modern TIMBER FRAME PANEL HOUSES on the basis of innovative technologies which was realized under the Single Programming Document. In the second quarter of 2007 we opened a Timber frame panel house production plant, which is one of the most modern plants of this kind in the Baltic States. We offer warm, economical and safe houses to private clients and companies.

Modern production facilities obtained from Sweden, highly-qualified personnel and the use of certified building materials guarantee rapid production process and high quality of the products. In 2007, KRIAUTE, LLC was awarded with the medal of the Ministry of Economy "Merits for Business" in the nomination "Development of Small and Mid-Size Business in Counties" (Panevezys County).

Assessment Commission's Protocol No. IA-119, valid from 25 April 2008 to 2013 April 25, grants the right to KRIAUTE, LLC to design separate parts of buildings, to construct a building or a separate part of a building and to maintain objects of Cultural heritage.

The company's modern manufacturing facilities are based on a 5-hectare site in the industrial part of Panevezys. We have 10 000 m2 of manufacturing space, where we produce structural and planed wood, different kinds of joinery products, wooden parts for furniture, metal products and metal constructions, garden houses and outdoor furniture.

Transportation services as well as timber drying, tenoning and planing services are also provided.

Our company cherishes its reputation. We carefully meet our commitments and seek to remain a reliable partner.

QUALITY

Our panel house production plant was launched in the second quarter of 2007. The manufacturing floor space is 10 000 m2, this includes space used for both - manufacturing and storage purposes.

Panels are produced by highly qualified specialists using Swedish technology and equipment.

The estimated production yield is 300 average size residential houses per year.

The basic elements of a panel house such as outside and inside walls, ceiling and roof (except roof covering, which is to be chosen by a client) are made indoors (therefore, the impact of atmosphere is avoided).Our engineers adjust the equipment to comply with the requirements of every project. Every house element passes quality control in the production-shop and only specially-trained highly-skilled employees work in the production area. In the course of production process we focus our attention on technical solutions ensuring high quality of products.Pre-fabricated elements are made by using computerized equipment, therefore the human impact on precision and quality of the final product is reduced. This is how high quality of products is achieved in our company.

The load-bearing structure of a panel house consists of wooden elements. Highest-quality wood with 15 % moisture content is used for production of panel house elements. Dried wood does not shrink or turn. We prepare timber in our factory, so we can assure the quality and control timely supply. This is an environmentally friendly material which makes your home cozy and comfortable.

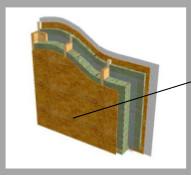

STANDARD STRUCTURE OF TIMBER-FRAME PANEL HOUSES

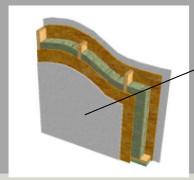

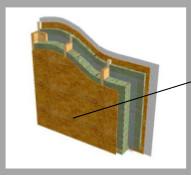

EXTERNAL WALLS

EXTERNAL WALLS

Wooden outside boards, clinker bricks, thermoinsulating panel

OSB board 12 mm

Wooden frames 45 x 145 mm

Thermal insulation 150 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

OSB board 12 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 W/m2K

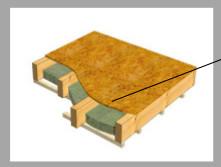

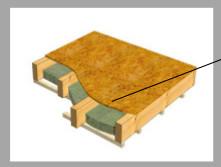

CEILING

CEILING

OSB board with tongue 22 mm

Wooden frames 60 / 45 x 220/ 200 mm

Sound insulation 100 mm

Wooden square beams 45 x 45 mm

Plaster board 12.5 mm

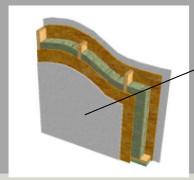

INTERIOR LOAD-BEARING WALLS / PARTITIONS

INTERIOR LOAD-BEARING WALLS / PARTITIONS

Plaster board 12.5 mm

OSB board 12 mm

Wooden frames 45 x 145/ 95/ 75/45 mm

Sound insulation 150/100/70/50 mm

OSB board 12 mm

Plaster board 12.5 mm

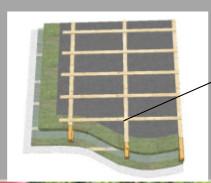

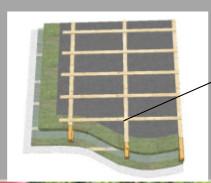

ROOFPANELS

ROOFPANELS

Wooden square beams 45 x 45 mm

Wooden square beams 25 x 45 mm

Diffuse film

Rafter 60/ 45 x 195 /220 mm

Thermal insulation 2 x 100 / 3 x 75 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 / 0.18 W/m2K

MODULAR PAVILIONS / CONTAINERS

Our modular containers are a flexible solution at low prices and can be produced on individual projects for housing, offices, building houses for temporary living, trade buildings and others. On the basis of the modular structure standing containers can be combined in different arrangements vertically and horizontally. We use metal structure where it is needed for stability, the rest of the structure is timber frame. They comply with the requirements for energy effectiveness and eco-design. Different sizes and numerous options for configuring components allows our products to match the requirements of the client.

We can offer fully assembled modules to be delivered on site, or separate panels delivered and assembled on site.

Advantage of our modules is fast assembly and dismantling.

Below you can see a scheme of the system we suggest for our clients. It makes it possible to have all space needed for temporary offices and accommodation. Unlimited number of modules can be placed side by side in a required sequence. They also can be put one on top of the other in max. 3 levels.

WOODEN WINDOWS

Why a wooden window is a good choice?

Wood is a natural long-lasting material which is perfectly suitable for buildings of different architectural styles;

Wooden windows save energy and your money;

Wood has the lowest thermal expansion coefficient if compared to any other materials used for production of windows;

Wooden windows do not accumulate electrostatic charges or dirt.

EURO 68/78 profiles of the new generation have a lot of properties which are inconspicuous at first sight, but which are very important and highly-valued by professionals.

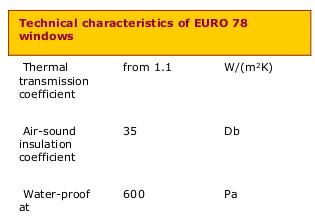

EURO 78

Warm wooden window

EURO 78 windows are 10 mms. thicker than Euro 68, therefore triple glass packets are usually set into them; this improves heat insulation and soundproof characteristics. Components of the window "Euro 78": 78 mm wooden profile made of wood chosen by a client (pine, larch, oak, etc.); German "Siegenia AUBI" fittings with an additional position of micro-ventilation; "Sikkens" paint, which ensures durability and aesthetical looks, is used for painting the windows.

Advantages of EURO 68/78 windows

EURO 68/78 profiles of the new generation with corners rounded more than it was usual and with inclination, which makes painting of the window easier and improves the quality of painting, and which also prevents accumulation of water and dirt and improves the looks of the product.

Tongue connections at the corners of window sash have ventilation of the opening for glass packet installation. The condensed water is removed through the drainage holes in the aluminium mould of the window frame.

The main seal at the bottom of the sash presses not to the aluminium mould, but to the wooden part of the window frame, therefore it does not freeze to it.

The outer horizontal plane of the sash is inclined by 200, thus enabling to easier remove snow, rain or dust.

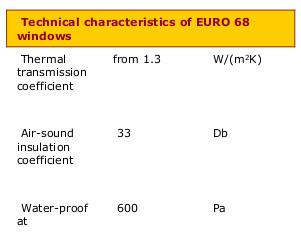

EURO 68

The most popular wooden windows in Lithuania

Components of the window "Euro 68": 68 mm wooden profile made of wood chosen by a client (pine, larch, oak, etc.);

German "Siegenia AUBI" fittings with an additional position of micro-ventilation; "Sikkens" paint, which ensures durability and aesthetical looks, is used for painting the windows.

We are looking for companies and enterprises that are able to represent our products: panel houses, wooden windows and processed wood in the countries of the European Union and in Scandinavian countries.

We are looking forward for offers leading to a close and mutually beneficial cooperation.

Are you looking for original ideas and yet untried materials? You can discover excellent quality of articles, design of forms and new possibilities of creation by trying the technology of artificial marble. The technology of artificial marble was designed in the USA. It has repeatedly received international awards for the possibilities to create articles of excellent qualities, design of forms and new production. Production of cultured marble represented the United States of America among 28 countries in the international fair of Geneva for two times and both times it was awarded with silver medal.

In Lithuania the production of this unique product was started in 1998 on behalf of "BALTIJOS MARMURAS".

Currently UAB "Baltijos marmuras" manufactures three types of production:

• cultured marble;

• cultured granite;

• solid surface “Dura Stone” (similar to “Corian” or “Cristalan”).

One of the basic advantages of the company "BALTIJOS MARMURAS" is the flexibility of production solutions. Various forms and colour gamma of products provide unlimited opportunities for the harmonization of interior colours and styles. This technology allows to obtain various colours that suit modern interior.

The production made from cultured marble or cultured granite especially fits in with the bathroom interior, i. e., sinks with tabletops of various forms and sizes, tables, windowsills, etc. Solid surface “Dura Stone” is one of the most durable and modern combinations of natural and synthetic materials. Solid surface is used for the production of tabletops, sinks, bars, wall slabs, windowsills and other products of various configurations and dimensions.

The areas of application of production manufactured by the company "UAB BALTIJOS MARMURAS" can be limited not by the properties of the material itself, but rather by the person's imagination. The imagination, of course, has no limits, therefore the possibilities of usage of these durable, nice, easy care materials certainly have not yet been explored as the articles produced by the company "BALTIJOS MARMURAS" are also easily fitted with other materials, e. g., metal, ceramics, wood, etc. Conforming to the highest quality requirements the production of "UAB

BALTIJOS MARMURAS" is certified in Lithuania

Solid surface "Dura Stone"

Solid surface "Dura Stone"

Produced according to the American technology solid surface "Dura Stone" is similar to "Corian", "Cristalan" and "Wilsonart" materials based on its properties. By using this homogenous material architects, designers and each one of us can implement our various dreams and enjoy a freedom of imagination. Solid surface "Dura Stone" is characterized with a wide range of applications. The material is used for the interiors of restaurants, cafes, bars, hotels, banks and offices; the production of kitchen, bathroom and laboratory tabletops; wall slaps, decoration elements. In addition, solid surface "Dura Stone" is used for the production of sinks integrated (casted) into tabletop.

Solid surface is resistant to scratches, various chemical liquids and is easy to clean. It is one of the most durable and modern combinations of natural and synthetic materials.

Being non-porous the structure of material does not absorb liquids and thus prevent from stains and spread of bacteria. In addition, the surface of these articles is warm and able to reach ambient temperature. Articles are characterized with easy care and restoration; scratches are simply removed by scrubbing.

Properties of solid surface “Dura Stone” are as follows:

- firm and durable,

- hygienic,

- seamless;

- resistant to moisture absorption;

- scratches are removed by simple scrubbing,

- resistant to heat up to +220°C,

- resistant to various chemicals,

- easy to mount,

- easy to restore and repair,

- many ways of formation;

- easy application with various materials,

- resistant to UV rays,

- wide range of colours.

Cultured marble

Cultured marble

Articles of cultured marble are produced from granulated marble powder and special binders. Cultured marble articles are of white colour and their surface is, at first glance, very similar to that of the ceramics.

However, the main advantage of cultured marble is the possibility to implement all ideas as the articles are produced for individual orders. Tabletops with sinks are connected in a seamless way as they are produced by casting. The form, place and number of sinks on tabletop can vary upon client's wish. The surface of cultured marble is smooth and glossy. Tabletops with sinks made of cultured marble and cultured granite may be fitted to various types of bathroom furniture. Cultured marble is also used for the production of white polished windowsills.

Cultured granite "SGA"

Cultured granite "SGA"

Articles of cultured granite are produced from shredded artificial granite granules and special binders. Articles of cultured granite may have both glossy and matted surface. Cultured granite can be used for casting of various articles: basins with tabletops of various forms and sizes with cast-in-place sinks of the same colour, windowsills, tables of various forms and other original production. Tabletops with sinks are connected in a seamless way as they are produced by casting. The form, place and number of sinks on tabletop can vary upon client's wish. Articles are absolutely resistant to moisture.

Become our partner

We invite furniture production companies, designers, architects and construction companies for cooperation.

We provide our partners with comprehensive information, production samples and catalogues.

We offer favourable prices and contract conditions.

Construction of houses pre-fabricated in plants has been the most popular house-building technology in the world for several decades. For example, in US 90% of houses have been built on the basis of wooden frameworks. In Sweden 80% of all houses have been made of wood and in Scotland - 48%. These numbers are constantly increasing in other countries too. This building method is considered to be economical, environment-friendly and requires low maintenance costs. Modern architectural tendencies, new building materials and the latest technologies provide more and more possibilities for production of panel houses.

European countries started developing production of panel houses 50 years ago. In Germany, Norway, Sweden and some other countries the majority of residents live in panel houses. Therefore panel houses are sometimes referred to as houses of the 21st century.

During recent decades the production technology of such houses has improved considerably due to the fact that modern equipment and building materials have been introduced. Modern panel houses not only stand their ground if compared to brick houses and timber houses, but have even surpassed them.

A panel house is constructed of panels which are made as follows: OSB boards are nailed to a wooden frame on the outside and on the inside. The inside of such a panel is then filled with stone wool and this allows to achieve the required thermal resistance. Such construction of buildings guarantees stable characteristics of thermal resistance during any season of the year. Houses built in accordance with such technologies are environmentally-friendly, they have good heat and energy saving characteristics and they are suited for living in them permanently.

Why a panel house is a good choice?

QUALITY

Automated production - ensuring high precision of products

Standard units - guarantee the absence of frost bridges

Production is fully controlled

Specially trained personnel works in the production process

SPEED

House assembly takes 3 to 5 days.

Contact us only once and specialists of UAB Kriaute will produce and assemble a house under a typical or individual project. Ready-made panels of up to 12 m length help to save time on the construction site.

House- assembly work can be done all year round

GUARANTEES

Only certified materials are used for production of houses

Post-guarantee service is provided

PRICE

Short assembly time - workforce to be hired for a shorter time

Light- weight building elements - simpler foundations

Pre-fabricated elements of a house are delivered to the construction site in due time - you do not have to take measures of precaution against theft.

INDIVIDUAL DESIGNING

KRIAUTE, LLC company's designers use a special computer program for preparing the structural drawings of a house. With the help of our designer a client himself can design a dream house, or he can choose an already available typical project. You are welcome to have a cup of coffee or tea and to see a sample house built by our company.

HOUSE CONSTRUCTION

Separating walls and separating floors

One of the most important requirements for separating walls and separating floors is their acoustic properties (i.e. airborne sound insulation). The typical assemblies of separating walls and separating floors used by our company allow us to comply with the sound insulation standards. Inside separating bearing walls achieve the value of at least 52 db, whereas inside separating non-bearing walls achieve the value of at least 36 db.

Outside walls and roof panels

One of the most important requirements for outside walls and roof panels is thermal insulation. Proper assembly of panels allows us to achieve in these structures the maximum thermal resistance which complies with the current requirements. The outside walls achieve the thermal resistance value of 5 sq. m K/W and the roof - the value of 6 sq. m K/W.

STANDARD STRUCTURE OF TIMBER-FRAME PANEL HOUSES

EXTERNAL WALLS

EXTERNAL WALLS

Wooden outside boards, clinker bricks, thermoinsulating panel

OSB board 12 mm

Wooden frames 45 x 145 mm

Thermal insulation 150 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

OSB board 12 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 W/m2K

CEILING

CEILING

OSB board with tongue 22 mm

Wooden frames 60 / 45 x 220/ 200 mm

Sound insulation 100 mm

Wooden square beams 45 x 45 mm

Plaster board 12.5 mm

INTERIOR LOAD-BEARING WALLS / PARTITIONS

INTERIOR LOAD-BEARING WALLS / PARTITIONS

Plaster board 12.5 mm

OSB board 12 mm

Wooden frames 45 x 145/ 95/ 75/45 mm

Sound insulation 150/100/70/50 mm

OSB board 12 mm

Plaster board 12.5 mm

ROOFPANELS

ROOFPANELS

Wooden square beams 45 x 45 mm

Wooden square beams 25 x 45 mm

Diffuse film

Rafter 60/ 45 x 195 /220 mm

Thermal insulation 2 x 100 / 3 x 75 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 / 0.18 W/m2K

PRODUCTION PROCESS

Our panel house production plant was launched in the second quarter of 2007. The manufacturing floor space is 10 000 m2, this includes space used for both - manufacturing and storage purposes.

Panel houses are produced by highly qualified specialists.

The estimated production yield is 300 average size residential houses per year.

The basic elements of a panel house such as outside and inside walls, ceiling and roof (except roof covering, which is to be chosen by a client) are made indoors in accordance with drawings. Every house element passes quality control in the production-shop. This is how high quality of products is achieved in our company. The bearing structure of a panel house consists of wooden elements. Highest-quality wood with 15 % moisture content is used for production of panel house elements. Dried wood does not shrink or turn. This is an environmentally friendly material which makes your home cosy and comfortable.

KRIAUTE, LLC cooperates with architects and designers. Our engineers can adjust the equipment to comply with the requirements of the project. Production takes place indoors; therefore, the impact of atmosphere is avoided.

In the course of production process we focus our attention on technical solutions ensuring high quality of products.

Specially-trained highly-skilled employees work in the production area.

Pre-fabricated elements are made by using computerized equipment, therefore the human impact on precision and quality of the final product is reduced.

To private individuals and entities the KRIAUTE, LLC offers building warm, economic and safe houses. Modern Swedish-make equipment, qualified staff and use of certified materials warrant high product quality and prompt delivery.